Specifically designed SIPs can form a loadbearing structural system for buildings up to 18 meters high. SIPs can also be used as a component of timber frame build systems. Taller buildings, and even high rises that use steel frames, also utilise SIPs as infill walls that sit within or outside the frame itself.

When used for external application, externally facing OSBs require waterproofing as moisture ingress could compromise the integrity of the board. Arctek performance overlay technology by Arclin is an alternative to traditional waterproofing membranes that is trusted by timber components manufacturers worldwide. The high-performance overlay solution is thermally fused with the OSB in the factory. Once installed, Arctek performance overlay technology provides a weatherproof shield that keeps moisture from penetrating the boards.

What is the standard size of a SIP?

There is currently no standardisation of SIP sizing or design. Typical product dimensions are 300, 600 and 1200mm wide and 2400, 2700 and 3000mm long, but SIPs can be designed to the structural and performance needs of a project.

Smaller panels have the benefit of easier transportation and handling on site whilst the larger panels will achieve better overall thermal performance. The weight per square metre should be taken into account as well. This varies depending on the insulation thickness and SIP design but at around 20kg/m2, the weight should be considered along with the size of the panel as it may pose a challenge for sites with difficult access or limited space.

Which materials are used for SIPs?

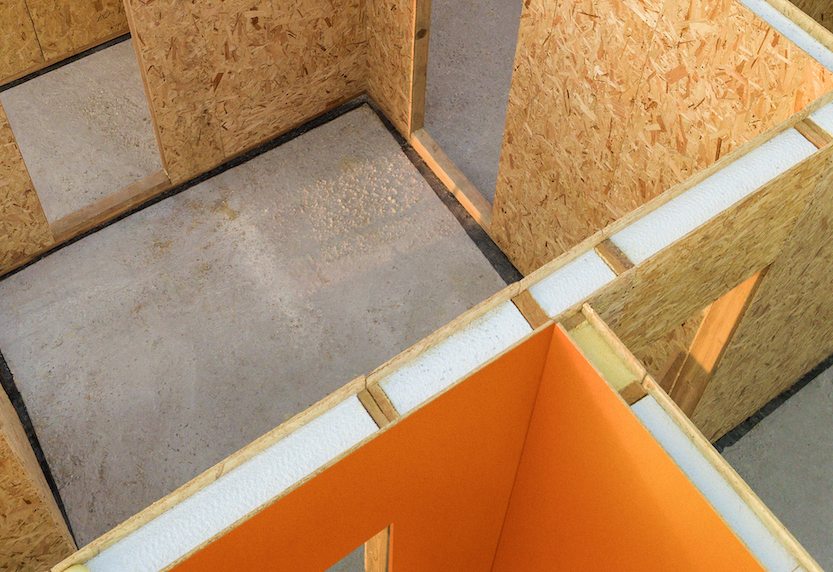

OSB rated 3 and above is generally used for both sides of the SIP, but other materials such as metal or plywood can also be used. OSB is the least costly of these materials. Along with the sustainability credentials, these are some of the reasons for their popularity.

A variety of insulation materials can be used for the SIP core. Whilst agricultural fibre such as wheat straw has been historically used, modern construction utilises lighter materials with higher R-values. The majority of widely specified SIPs will use expanded polystyrene rigid foam insulation (EPS), polyurethane (PUR) or in some cases Polyisocyanurate (PIR). The U-value of the SIP will depend on the type and thickness of the foam core. Regardless of the core makeup, all types of SIPs provide a relatively straightforward route for building regulations compliance across England, Scotland, and Wales.

How do you join SIPs together?

To gain the best U-value, the SIP joining systems must be effective in preventing air leakage and avoiding thermal bridging.

We already touched upon the fact that there is a lack of standardisation in the design of SIPs and this extends to the joining systems. Some manufacturers use a system akin to male to female connection that uses a timber stud to connect the panels whilst other provide so called ‘cam lock’ systems. SIP tape can also be used to minimise air leakage.

C24 timber is used to join SIPs to structural joints that use structural steel, lintels, or glulam beams. Increasingly manufacturers use custom SIP spline jointing systems. These are essentially insulated mini panels that are fitted inside the joined panels, thus helping to lower the U-value of the fitted wall.

Added protection to SIPs

We already discussed the benefits of Arctek performance overlay technology by Arclin when used as a moisture barrier and vapour control layer for the OSBs used for SIP manufacture. It is crucial to consider that the requirements of each project will differ. Geographical location and position, buildings design and various other factors determine the type of finish required for the SIP. Arctek is custom designed and formulated to suit project objectives. The SIPs are protected as soon as the overlays are bonded with the OSBs arrive on site protected and ready to install.

To find out more information on how Arclin’s Arctek performance overlay technology can improve the performance of SIPs, or to further discuss the benefits of our ground-breaking and proven technology, contact us today.