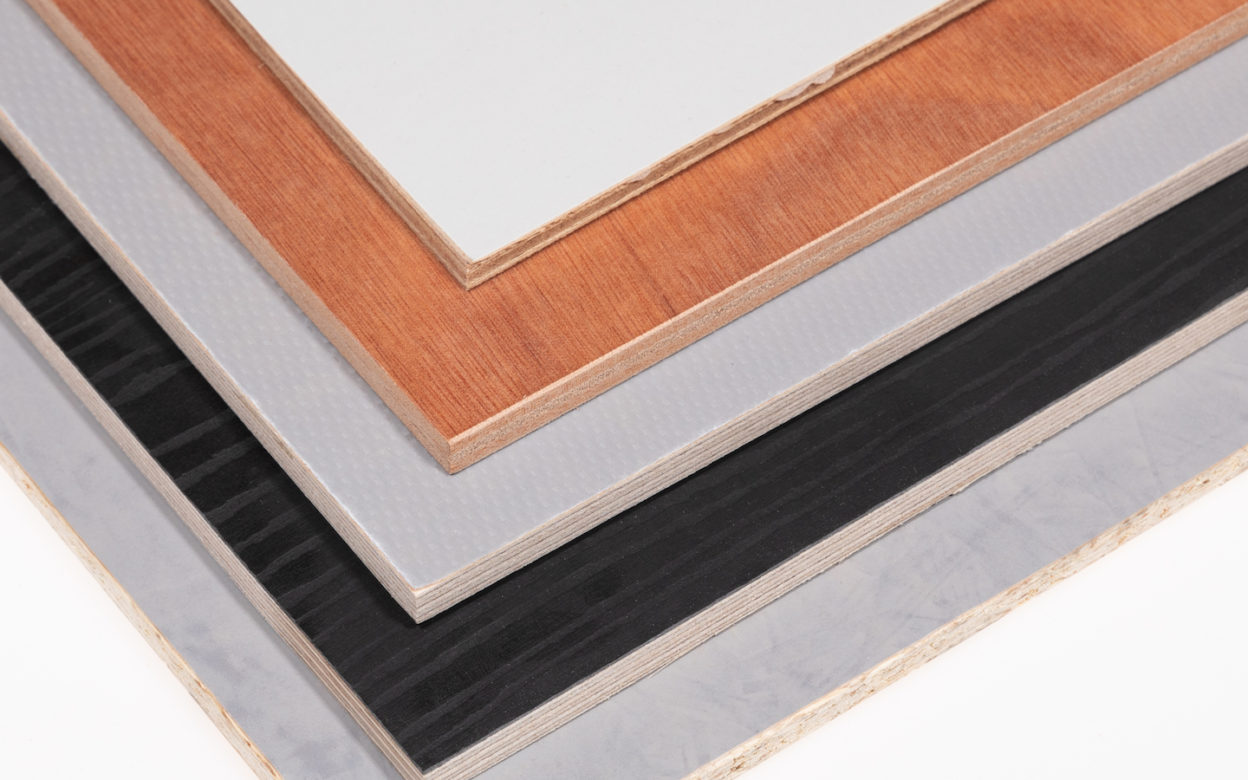

They can be custom made to suit the objectives of a specific application. The most used overlay solutions create moisture and vapour barriers to protect oriented strand board (OSB), particle board, medium density fibreboard (MDF), plywood and other timber products.

High performance overlays can control the vapour transmission of the OSB board, which is relevant for where the boards are used to premanufacture components such as structural insulated panels (SIPs) and roof and wall cassettes.

If a smooth surface is required, high performance overlays can save valuable time. It is possible to sand the board, which is a laborious task that must be repeated, and the results are often underwhelming unless a filler is used. Overlays can resolve these challenges and can achieve a smooth uniform surface. They can also offer a primed base for further finishing layers which means the overlay can offer a high quality, uniform finish for the boards.

Unlike traditional moisture and vapour membranes, overlay solutions are thermally fused with the OSB and other wood based panels during manufacture. The technique means the overlays can achieve the highest level of performance.

Can overlays be used outside?

There are different types of overlays, however, high-performance overlay solutions such as Arclin’s Arctek technology, are designed for external use.

Weatherproofing overlay protects the board from moisture ingress and helps extend the design life of timber manufactured products.

Arclin is the leader in the design of overlay solutions and Arctek performance overlay technology provides the highest level of performance. Each overlay can be customised to the requirements of the panel manufacturer and offer one or a combination of the enhancing features.

To find out more information on how Arctek performance overlay technology can improve the performance of wood based panels and modern construction components made using timber manufactured products, contact us.