What are the drivers for timber based panels?

As the forecasts for timber based building products remains strong, the emphasis upon enhancing the performance of timber becomes greater too. It is clear from market data that consumers understand the importance and are showing commitment to wood based products with major drivers including sustainability, value and reducing CO2. Arctek® overlays are designed to fulfill these requirements by extending and improving the performance of timber substrates. These requirements are reflected in our extensive portfolio designed to meet market demands. Having chosen the most suitable surface solution for your requirement, choosing the correct adhesive ensures application is easy and efficient, but what are the choices?

Choosing the right adhesive

When selecting the correct adhesive, identifying where your timber based panel will be used is the first major consideration. Will the finished product be required for internal or external use? If it is internal, consider whether it will be a damp environment or whether the overlaid panel will have dual use – internal and external. In terms of cost, a less expensive (by the kilo) interior product may be more suitable than an exterior grade product. However, it is important to consider how the adhesive has to be applied and how well the adhesive system meets your needs.

In the following section, we explore the types of adhesives available and consider their shared and differing features. Each system brings its own unique qualities.

Polyvinyl Acetate PVA

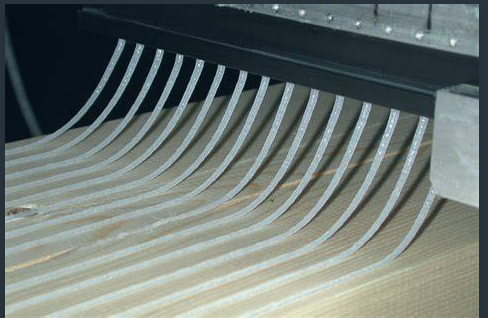

PVA adhesives are ideal for paper based overlays and can be applied using a simple roller coater or, in some cases, can be sprayed. The PVA adhesive after it is applied, (usually to the substrate) needs some time to bond properly. This requires some kind of pressing, i.e., holding the parts together while the moisture in the PVA is absorbed by the substrate and the overlay (if possible). A cold press is a proven method to accomplish this. Stacks of glued up products are moved into a cold press and may sit under pressure for a few hours or more while the adhesive does its work. Overall production is limited to how long the product takes to put together (make the sandwich) and how long it has to sit in the press. The overall size of the press is also a major factor to consider.

There are ways to speed up the PVA process, for example, adding heat in the form of a hot press (although used as a warm press), which can increase the production volume. PVA is a water based adhesive so a hot press in most cases should not apply more than 100 degrees Celsius. Too high and the water in the adhesive will boil and cause issues. Typically, a hot press can process a panel in 30 – 45 seconds. In order to increase productivity, more openings or Daylights can be specified when considering the press. This will allow for more than one “sandwich” to be pressed at a time. PVA adhesive is a Thermoplastic, which means it can be softened and reactivated using heat, making it less than ideal for surfaces exposed to heat.

Contact Cement

More expensive per kilo than PVA, but very easy to use in a small shop is Contact Cement. It is an adhesive that can be applied to both substrate and laminate and pressed together using a nip roller or a simple, rubber covered, pressing roller. Contact Cement adhesive are easy to use; usually sprayed on and allowed to dry. Due to surface inconsistencies resulting from spraying, these are best covered up with a thick laminate or backed veneer. The very basic installations are affordable, requiring only a bench to spray material and a nip roller.

Epoxies

Epoxies are also known as two-part adhesives and can offer great bond strength with a strong surface. Epoxies can be mixed in a glue holding area on the application equipment and are usually combined batch-to-batch. The reason being, epoxies when mixed (with a catalyst) will eventually set up and cure on their own. Therefore, the term known as “pot life” must be considered. Epoxies can be used in pressing equipment and continuous or feed-through equipment, for example, roller presses or lamination lines.

On a roller or Continuous Lamination operation, the two parts can be applied on separated coaters; part one on the board and part two on top of the previously coated board. This is called a “wet on wet” system, which works well with Urea Formaldehyde systems. Two-part systems such as these usually create a harder surface than a water-based PVA system. Two part adhesives are usually thermoset and are heat resistant.

Hot PUR Melt Polyurethane Reactive Adhesives

For a product that is suitable for interior and exterior use, hot melt PUR is ideal. Liquid PU or Polyurethane is also a good solution. However, hot melt PUR is a great solution for exterior use or applications where the final product may be exposed to heat or moisture. PUR requires specific equipment to apply it to either the substrate or the overlay. PUR is considered a low temperature (130 degrees Celsius) product and is moisture cured. Low temperature hot melts are great when laminating heat sensitive materials such as PVC overlays. It is important to note that a moisture cure adhesive must be dispensed in an airtight melting device and application equipment that is not airtight must be cleaned after use.

Further Information

The relevance of choosing the most suitable adhesive for laminating onto timber panels is unique to each manufacturer’s requirements and the end-use application. By enhancing the performance of timber panels using Arctek® surface solutions, manufacturers are helping to meet customer demand for wood-based construction.

This article outlines the general framework for choosing an adhesive. However, the Arctek® team is available to discuss your requirements in detail. For further insight and product information, please contact Arctek® using the Make an Enquiry icon above.