Wood ticks key eco-friendly boxes. Unlike finite resource-based steel, concrete, plastic and aluminium, if sustainably sourced it’s renewable. While these rival materials generate CO 2 through extraction and production, timber absorbs the greenhouse gas as it grows and holds on to it for life. That makes wood-based buildings long-term and potentially major climate change-mitigating carbon stores. Moreover, wood is relatively low energy in processing and a natural insulant.

Timber frame buildings are on the agenda

In December the Timber in Construction Working Group (TiC) released its roadmap for ‘actions needed to increase construction of timber and wood-hybrid homes’. Backed by the TiC Innovation Fund, these include driving research into timber building as part of a sustainable, circular bioeconomy and increasing efficiency and productivity of timber construction.

Also last year came announcements from Barratt, Taylor Wimpey and Persimmon that they are all building multi-million-pound new offsite construction timber frame factories. Vistry also reopened the 356,000ft2 timber frame ‘mega factory’, which it acquired when Countryside Partnerships became part of the group. So, with decarbonisation now the construction sector buzzword, the future for building in wood looks bright.

At the same time, timber frame and other timber-based construction specialists share some of the pressures of the wider building industry. That includes contending with a mounting building skills shortage and introduction of ever more exacting construction standards to drive building technical performance and environmental performance.

Arctek® Dryshell™ – A new generation successor to more traditional house-wrap membranes

It’s this combination of timber building opportunity and challenge for providers that forms the background to US-based Arclin now targeting Arctek® Dryshell™ at the timber frame sector in the UK as well as the rest of Europe where the industry shares similar imperatives.

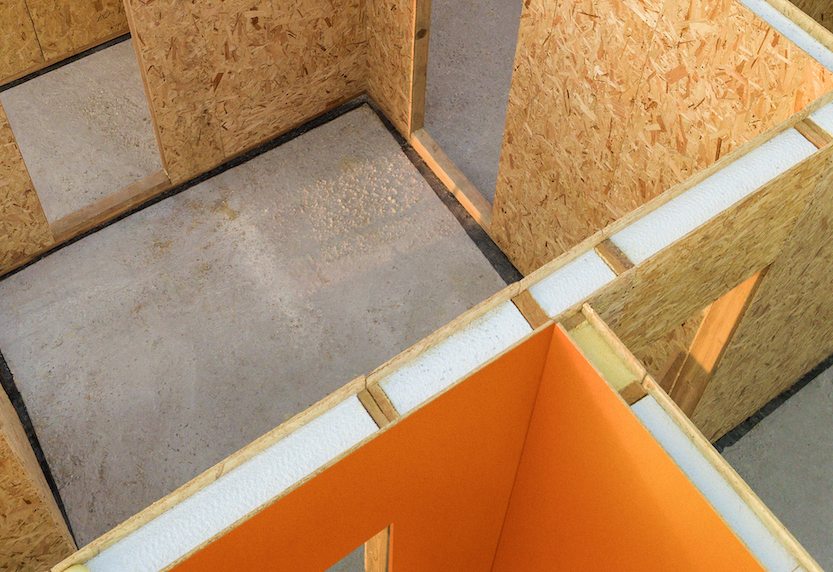

Arctek® Dryshell™, easily identified by its distinctive turmeric colour, is an integrated weather barrier and vapour control layer for wood panels used in timber frame construction. It comprises a proprietary resin formula Impregnated into an overlay paper which is thermally fused to the panel. It provides protection against external moisture ingress and interstitial condensation in the timber frame envelope – both of which, of course, can compromise wood components’ performance. It’s a technology that is billed as a new generation successor to the more traditional, site-fixed polyethylene house-wrap protective, vapour control membranes.

Complying with tougher building regulations

Arclin believes it can help the timber frame sector rise to meet new demands on construction in the UK and Europe and make the most of its potential. Latest UK construction standards developments include the 2021 toughening up of Building Standards Part L on energy performance and part F on ventilation. The objective is buildings with an effective thermal envelope combined with ventilation systems that prevent excessive interior humidity and consequent damp and mould growth. These revisions are first steps towards the 2025 introduction of the Future Homes Standard (FHS).

These more demanding rules are accompanied by an increased focus on performance gaps, the degree to which the performance of finished buildings falls below designed performance. This can be due to a range of factors but include building solutions not living up to theoretical performance and poor installation of building components and systems. To tackle this, the new Part L includes the requirement for photographic evidence of key details during construction to ensure they are completed correctly.

When it comes to building energy efficiency, timber framed buildings, such as those using prefabricated cassettes or structural insulated panels (SIPs), inherently minimise performance gap risks. They provide high levels of insulation and airtightness, combined with controlled ventilation and are consequently frequently used in housing aiming for the Passivhaus standard, with its focus on building envelope performance.

However, these timber-framed building approaches also most commonly use those site-fixed plastic housewrap membranes for moisture protection of timber envelope, vapour control and added airtightness. But these need expertise to ensure accurate overlaps at complex details. They are also prone to snagging and tearing, allowing in moisture and dirt.

Arctek® Dryshell™ underpins timber frame quality

Arctek® Dryshell™ overlay eliminates the risks inherent in using these membranes. Factory-applied, it provides a consistent, uniform protective and vapour control layer across OSB, plywood and other wood-based sheathing board – and it can also be applied to SIPs. With timber frame panels delivered ready-protected, it saves site time, and with panel joints simply taped, it’s proven to enhance airtightness.

Modern methods of construction (MMC) build momentum in timber frame construction

Another urgent task facing UK builders is simply to build more. The population is forecast to grow from 68 million now to 71 million in 2045. Further driving the need for new homes, the number of single households has grown 8.3% in the last decade and is expected to increase further due to lifestyle choice and an ageing population. The proportion of people living in urban centres is set to rise too, from 83.9% to 90.2% in 2050 – so more dwellings are needed.

The Government estimates the UK should be building 300,000 homes a year. Yet the annual average for the decade to 2022 was just 178,000. Output increased encouragingly to 204,500 last year, but it’s accepted something must change to increase that by another 50%. One way to up the ante is seen as greater uptake of offsite, or modern methods of construction (MMC), with home components prefabricated in factories and delivered in kit-form for rapid assembly on site.

The government sees it as a way forward, as underlined by its offsite solutions framework. This involves the Crown Commercial Service allocating public construction projects, from social housing to schools and healthcare facilities, to builders using offsite modular approaches, with the programme estimated to have a value of up to £10 billion.

The offsite MMC approach is seen as improving housing industry productivity and environmental performance due to the higher spec and quality of building assemblies possible in controlled factory conditions. And given timber’s lightness and strength to weight, plus its ease of processing relative to concrete and steel, it is increasingly seen as the ideal material for offsite building manufacture – prime evidence of which is the significant investment in new offsite timber frame factories by the housing majors.

Arclin maintains that Arctek® Dryshell™ and offsite MMC is a perfect match. Applied to wood panels used in the latter, it further drives the efficiency, sustainability and assured quality of this way of building. It enables even more complete building assemblies to be produced, incorporating wood panel moisture protection and vapour control, for still faster erection.

Tackling the construction skills shortage

Another driver for offsite is the UK’s mounting building skills shortfall. According to the Construction Skills Network, 25% of the current construction workforce will retire in the next 10 to 15 years. At the same time, says the CSN, recruitment is falling. The result is that as soon as 2027, UK construction will be short 225,000 people. CertainTeed, the subsidiary of building products giant Saint-Gobain, sees offsite helping in two ways “The modern, tech-oriented nature of offsite construction, integrating computer-aided design and automated machinery, [can drive recruitment] by appealing more to younger generations,” it says. “Offsite construction also maximises the output of the existing workforce, with workers in a factory setting often focusing on specific tasks, streamlining the construction process and allowing for faster production with fewer hands.”

Arctek® Dryshell™ contributes here too. Eliminating the need for site-fixed protective, vapour control membranes, further deskills the timber frame building process.

Arctek® Dryshell™ – A waste-free vapour control solution

Also central to UK construction improving its environmental performance is reducing its waste, five million tonnes of which still go to landfill annually. Using Arctek® Dryshell™ also means offcuts of plastic house-wrap membranes don’t contribute to that total. Sounding out UK timber panel processors and producers, Arclin says they recognised the potential of Arctek® Dryshell™ for raising the performance and value of their products for timber frame customers. And they said they were excited to use it.

Arctek® Dryshell™ meets timber frame needs Europe-wide

Companies in the EU gave the same response. The construction sector has many of the same challenges as its UK counterpart; the need to increase output, build better and more sustainably while also facing labour shortages.

The Green Deal strategy for making the EU carbon neutral by 2050 also has construction decarbonisation as a central tenet, and increasing timber building as part of this is front and centre of policy. Speaking at the European Bauhaus ‘into the woods’ event, EU president Ursula von der Leyen said that ‘building with timber…. could turn our homes, even entire cities into carbon sinks’. At the same time, European offsite modular building is projected to increase in annual value from the current €18.4 billion to €27.3 billion in 2030.

Individual EU member states are also pressing ahead with their own policies to drive timber building still further. France is a prime instance. As part of its RE2020 environmental regulation, the French government stipulates that new public buildings should comprise 50% bio-based materials.

By choosing Arctek® Dryshell™, timber framed housing manufacturers and suppliers can make improvements to their processes and take greater advantage of the growing timber frame market in the UK and the EU. To find out more about how Arctek® Dryshell™ can benefit your timber framed housebuilding projects, request a sample or contact us with an enquiry.