PRIMARY PRESS

Arclin identifies the lamination process into two basic groups; primary and secondary lamination. Primary Lamination takes place during the manufacturing of the substrate. As an example, when a manufacturer is composing a substrate, usually in a wood based operation, our overlay material is placed in the press along with the wood based components. These are pressed together to create a panel with an integrated, high performance overlay. In this scenario, our overlay material has a dry glue line incorporated on it, in order for the overlay to adhere to the newly formed panel. Using this process, Arctek® Dryshell overlay can impart water resistant properties on the exposed side, whilst retaining breathable properties on the wood based side. The purpose behind the surface solution is to prevent moisture being captured in the substrate, but simultaneously allowing moisture to exit through the adhesive and overlay. This prevents the potential for mould and rot and provides a smooth, aesthetically pleasing surface to rough and un-sanded surfaces.

SECONDARY LAMINATION

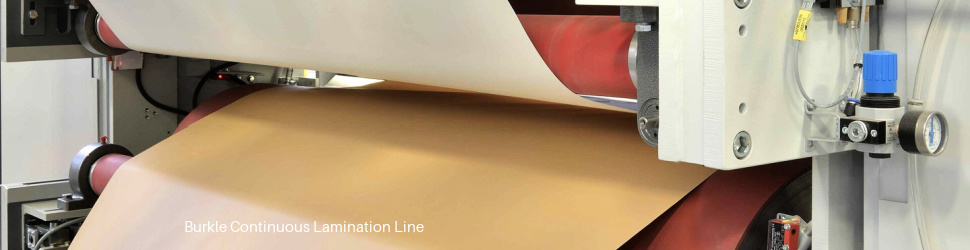

The benefits of Arclin overlays are enjoyed by the largest wood based panel manufacturers in the world, but there are many more manufacturers purchasing substrate without an overlay seeking to create a high performance, value added product for regional markets. This is what Arclin refer to as Secondary Lamination and is one of the many benefits of the Arctek® product range; whereby manufacturers can apply an overlay, decorative as well as functional, to a substrate to increase its value in the marketplace.

Secondary lamination requires three basic components, substrate, adhesive, and overlay. This process is available to the smallest of shops through to the very largest of manufacturers. Processes are scaled to meet production requirements, environmental demands as well as an understanding of the properties to be imparted into the final product.

CONSIDERATIONS

The questions manufacturers consider when determining their secondary lamination process include the following:

- What properties are needed for the product?

- Interior or exterior applications?

- What adhesives work with which laminate?

- What equipment is needed to make the product?

- What is the volume of laminated panels required?

- How much investment, if any, is necessary?

FINDING THE RIGHT SOLUTION

The Arctek® by Arclin team has a wealth of experience, knowledge and expertise to help producers answer these questions. In addition to providing surface solutions, Arctek® by Arclin also provides support to overcome questions on trialing throughout the process until and beyond roll out. Once established, the Arctek® team remains on hand to assist your organization as it develops and grows.

For further information on how Arctek® ® performance overlay technology can improve the performance of OSB, plywood and other timber manufactured products, contact us using the link.